■

AUTOMATED/ROBOTIC PALLET INSPECTION SYSTEM

Avoid production stops with automated pallet control

At Ferrum Group, we have developed a range of automated/robotic pallet inspection and handling systems with different functionality and capacities to meet all industry needs. Our pallet control solutions focus on preventing production downtime due to defective and unhygienic pallets. Automated inspection and sorting of pallets increases quality and capacity compared to manual pallet checks. The result is higher output and minimization of pallet defects in the production.

Be inspired by our product video highlighting our solution’s functionalities and benefits.

Easy and efficient handling and inspection of pallets

- Robotic and camera technology of the highest quality

- Easily operated by one person through Siemens HMI S7 touch panel

- Easy overview of sorted quantity of pallets

- Safe and stable handling of pallet top frames

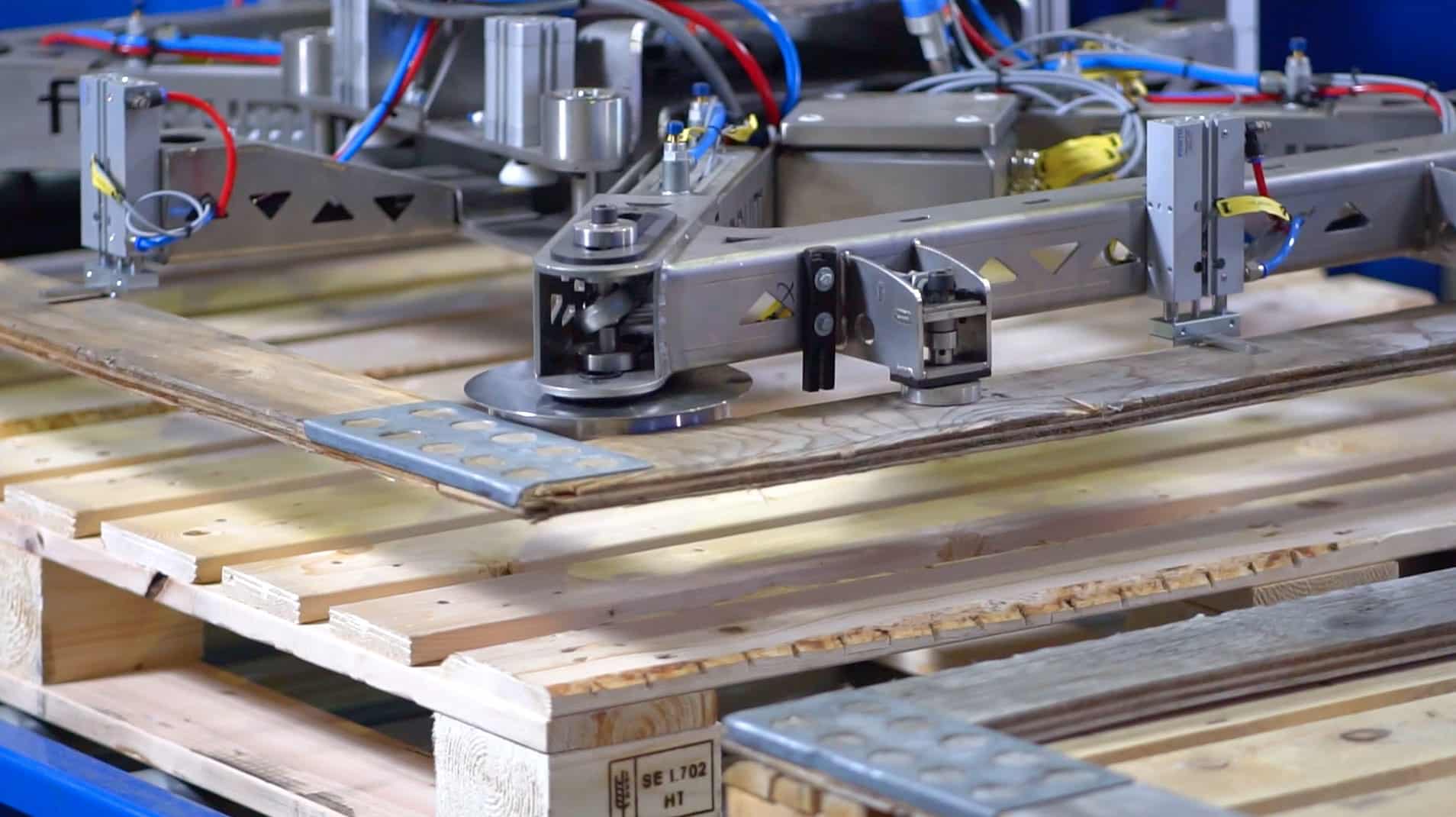

- Nails are automatically pressed into the pallet at the nail press (not Palletscan 100 – standard)

- Brush function automatically removes dirt from the pallet surface

- Integrated scanning station scans top frames and pallets with high resolution camera technology

- 8 3D cameras provide thorough visual inspection of pallet condition

- Option to scan color and humidity

- High security and easy access to infeed and outfeed of pallets

- Plant with capacity from 80-240 pallets per hou

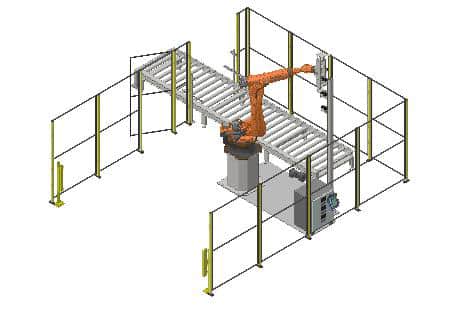

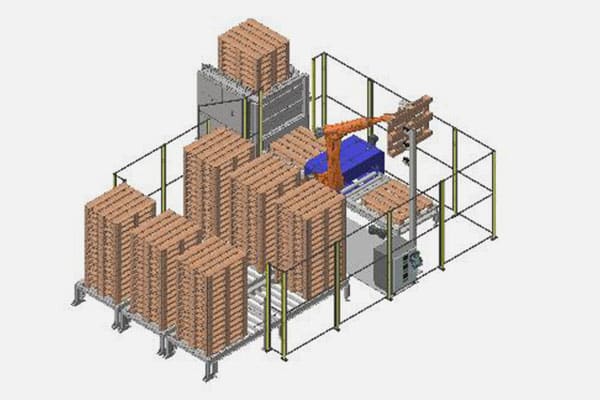

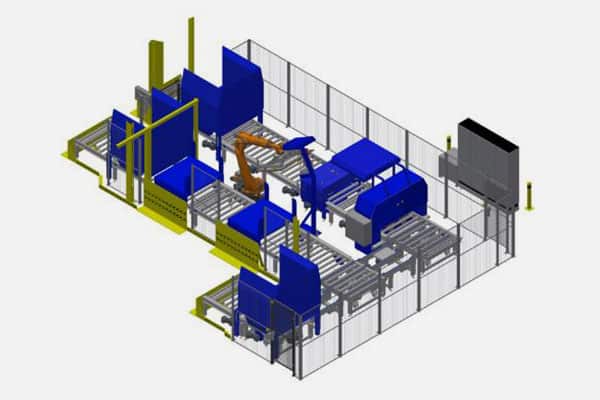

Palletscan 100 – Standard

- Pallet stack delivered at inlet where robot handles pallet

- Control/inspection via vision system

- Pallets are placed in stacks on the floor in 3 sorts

- Optional pallet lanes for automatic pallet outflow and buffer available

- The system handles EUR and UK pallets

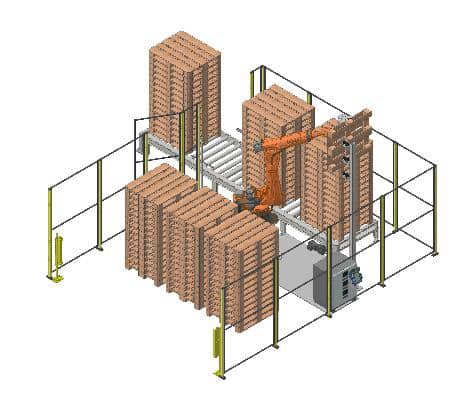

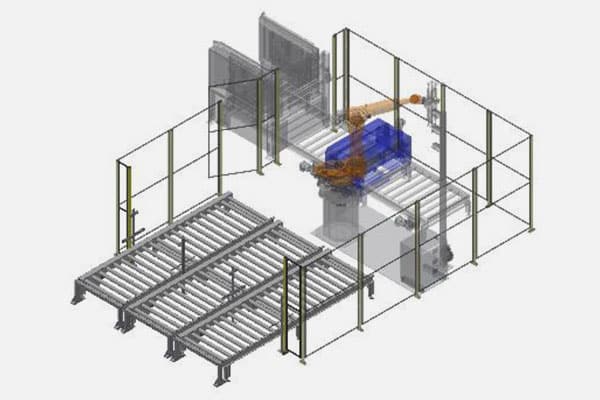

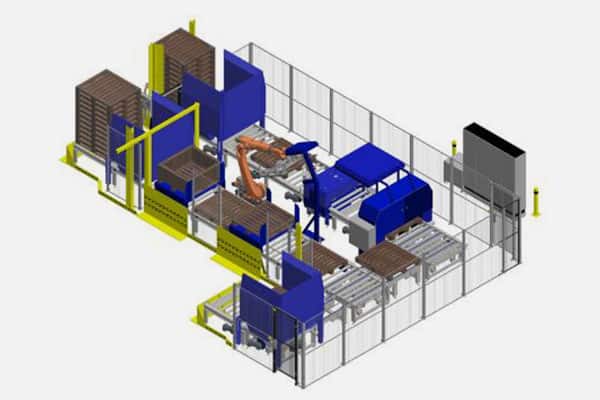

Palletscan 100 – PLUS

- Pallet stack delivered in pallet magazine

- The robot handles the pallet feeding it through the nail press and the weigher

- Pallet inspection via vision system

- Pallets are placed in stacks on the floor in 3 sorts

- Available options:

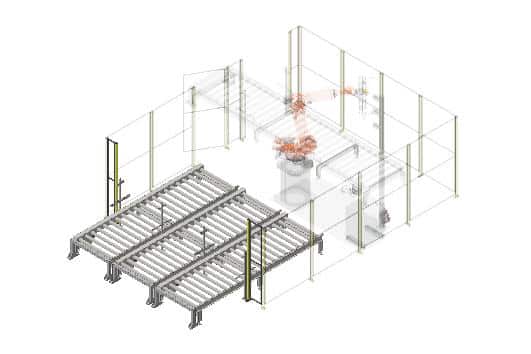

- Pallet conveyors for automatic pallet discharge and buffer

- Extraction, independent unit

- Waste conveyor belt at nail press

- The system handles EUR and UK pallets

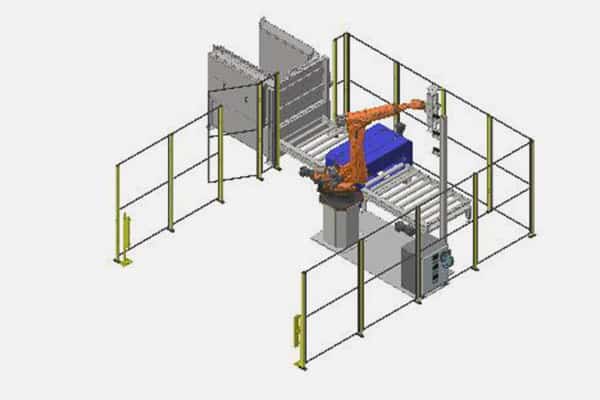

Palletscan 240

Palletscan including top frame sorting

- The system sorts both pallets and pallet top frames.

- Capacity: 135 pallets per hour

- The system handles EUR and UK pallets

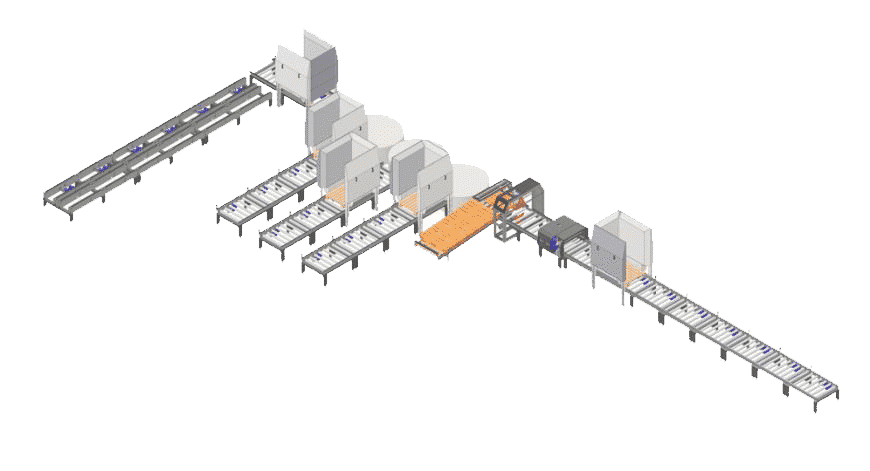

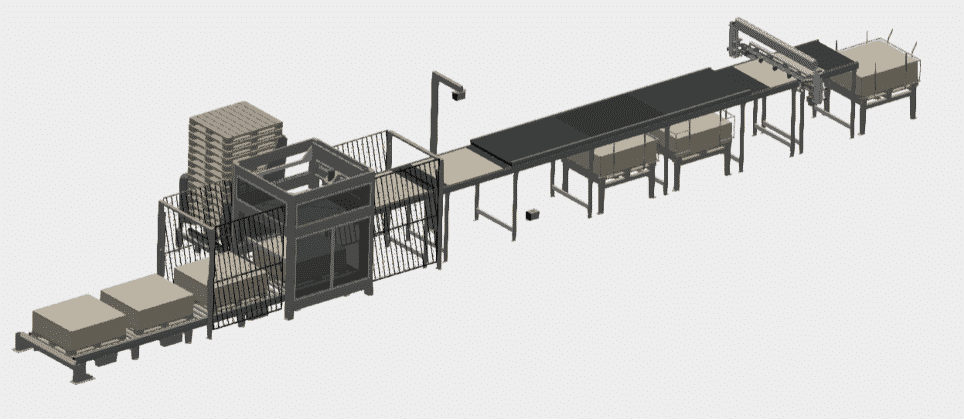

Sorting and cleaning solution for intermediate layers

In Ferrum Group, we have designed a solution to handle the sorting and cleaning process of recyclable intermediates, typically cardboard or plastic. The aim of the solution is to minimize manual costs associated with sorting and cleaning as well as to ensure consistent quality of the intermediates.

The design can be adapted to specific needs, e.g. the solution can be designed to scan both sides of the trays or only one side. The solution can be delivered with or without a cleaning unit.

The capacity of the solution depends on the scanning requirements and the general condition of the trays. The estimated capacity for scanning, sorting and cleaning is around 800 trays per hour.

The sorting and cleaning line will typically be located parallel to the pallet sorter in order for easy operation by the same operator.

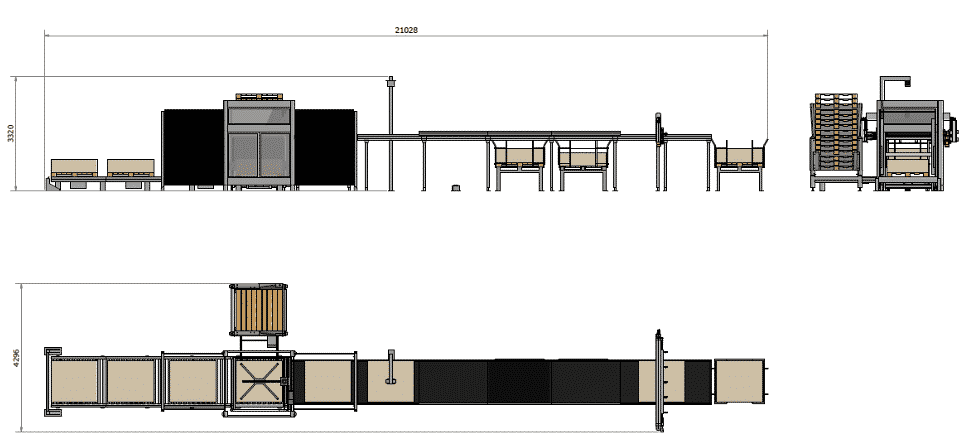

The layout illustrates a complete unit with scanning on both sides and cleaning unit.

Design og layout

- Pallets with intermediate layers are placed on the infeed conveyor and fed to the feeder station

- Intermediate layers are scanned on the top side

- Intermediate layer is fed to scanning station 2 where the intermediate layer is scanned from the underside (vacuum conveyor)

- Presorted intermediates are distributed according to the scanning procedure in two stations

- Approved trays are transported through the cleaning unit where both sides are cleaned

- Approved trays are stacked on a pallet

If you have any questions about our sorting and cleaning solution for intermediate layers, please feel free to call co-director Carsten Jørgensen, phone: +45 51 25 51 58

CARSTEN CAN HELP YOU WITH FERRUM GROUPS PALLET INSPECTION SYSTEM

Visit Ferrum Group’s LinkedIn company page

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten’s LinkedIn profile