■

Stainless steel tanks at highly affordable price points

Save 50 % or more – high quality stainless steel tanks sourced from the best Chinese manufacturers.

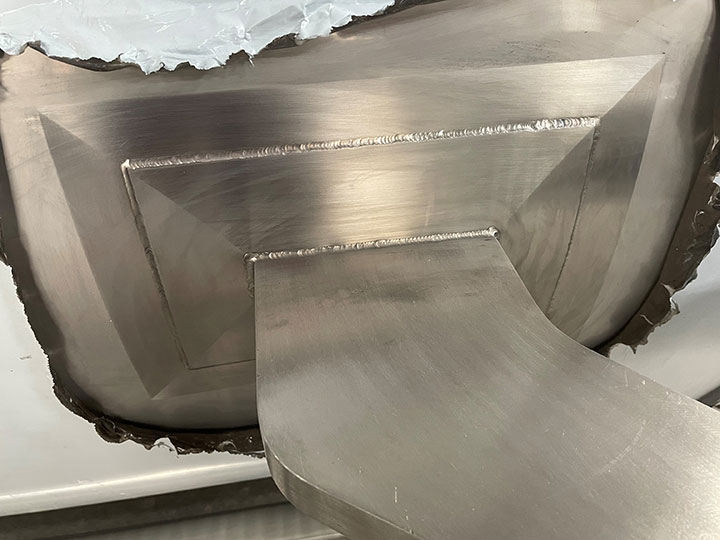

In Ferrum Group, we collaborate with the best Chinese manufacturers of stainless-steel tanks, including buffer tanks and jacket tanks with mixer for use in various industries, notably breweries, dairies, food production, as well as chemical and pharmaceutical industries. All stainless-steel tanks are of top quality and meet European standards and hygiene requirements.

Scroll down this page or click HERE to see price examples of buffer tanks and jacket mixer tanks in different volume sizes. We often find that our prices are 50% or lower than those of European tank manufacturers. We can supply stainless steel tanks in all sizes and with all functionalities – the examples are merely for illustration.

If desired, our engineers and machine factory can handle the design and production of piping and other process equipment. Additionally, we can manage the installation of stainless-steel tanks onsite through our own team or network of partners. Ferrum Group serves Danish industrial companies such as Carlsberg, Arla, Royal Unibrew and Orkla with process equipment as well as robotic and automation solutions.

Stainless steel buffer tanks – price examples for different unit volumes

Please see below examples of different stainless-steel buffer tanks – ranging from 2,000 to 10,000 liters in volume.

All buffer tanks can be delivered according to your specifications.

Please contact Ferrum Group Sales Director Carsten Jørgensen by phone at +45 5125 5158 or via email at caj@ferrum-group.dk for any inquiries or price quotations.

Click here to fill out the contact form.

Buffer Tank

2000L- V=2000L

- SUS304

- touch parts with material SUS316

- single layer

- tank body φ1490*1220*3mm

- breathing hole

- sampling valve

- CIP ball-type sprayer

- climbing ladder

- glass tube liquid level

- four adjustable legs

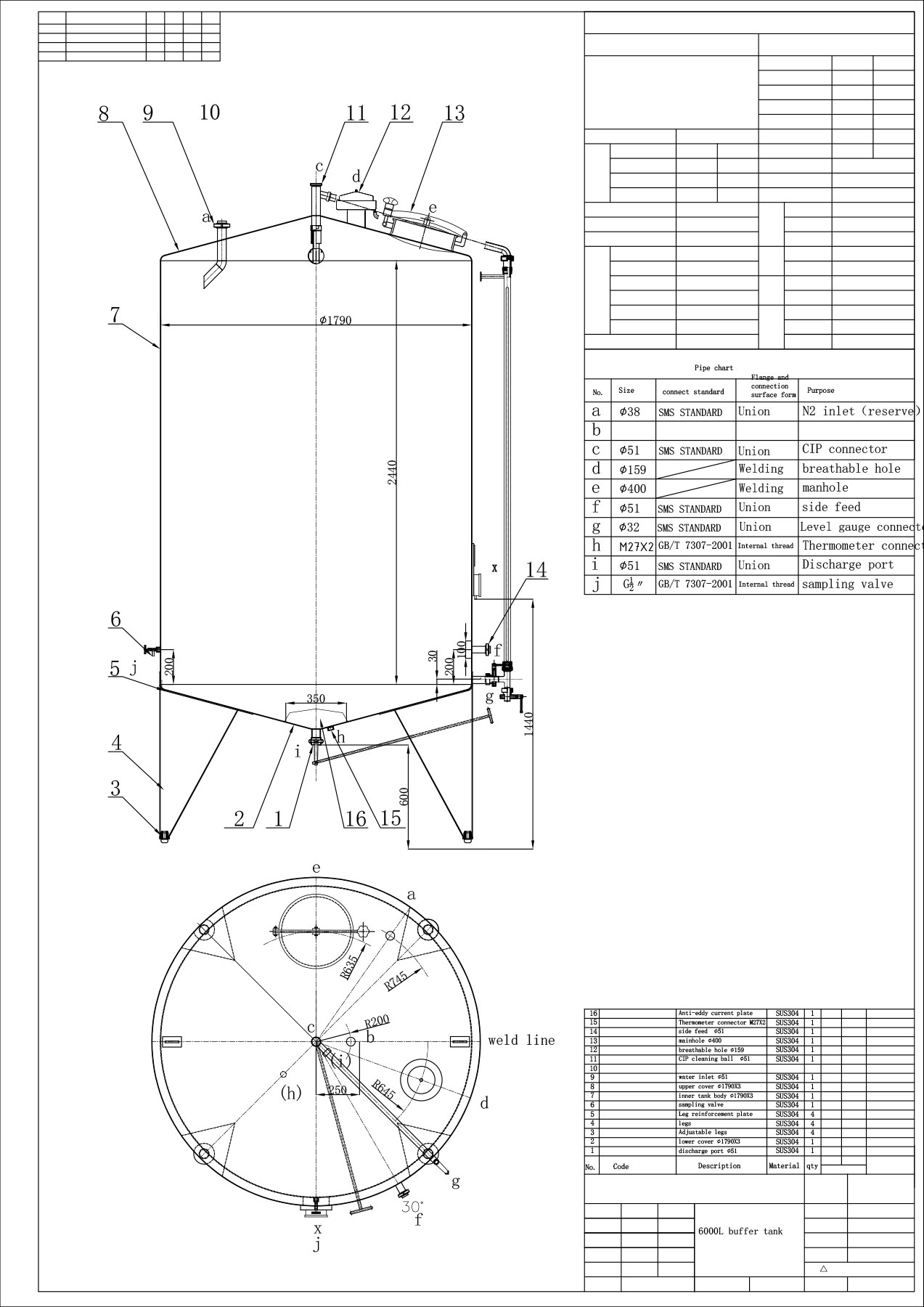

Buffer Tank

5000L- V=5000L

- SUS304

- touch parts with material SUS316

- single layer

- tank body φ1630*2440*3mm

- breathing hole

- sampling valve

- CIP ball-type sprayer

- climbing ladder

- glass tube liquid level

- four adjustable legs

Buffer Tank

10000L- V=10000L

- SUS304

- touch parts with material SUS316

- single layer

- tank body φ2070*3000*3mm

- breathing hole

- sampling valve

- CIP ball-type sprayer

- climbing ladder

- glass tube liquid level

- four adjustable legs

Stainless steel jacket tanks with mixer – price examples for different unit volumes

Please see below examples of different stainless-steel jacket tanks with mixer – ranging from 2,000 to 10,000 liters in volume.

All jacket tanks with mixer can be delivered according to your specifications.

Please contact Ferrum Group Sales Director Carsten Jørgensen by phone at +45 5125 5158 or via email at caj@ferrum-group.dk for any inquiries or price quotations.

Click here to fill out the contact form.

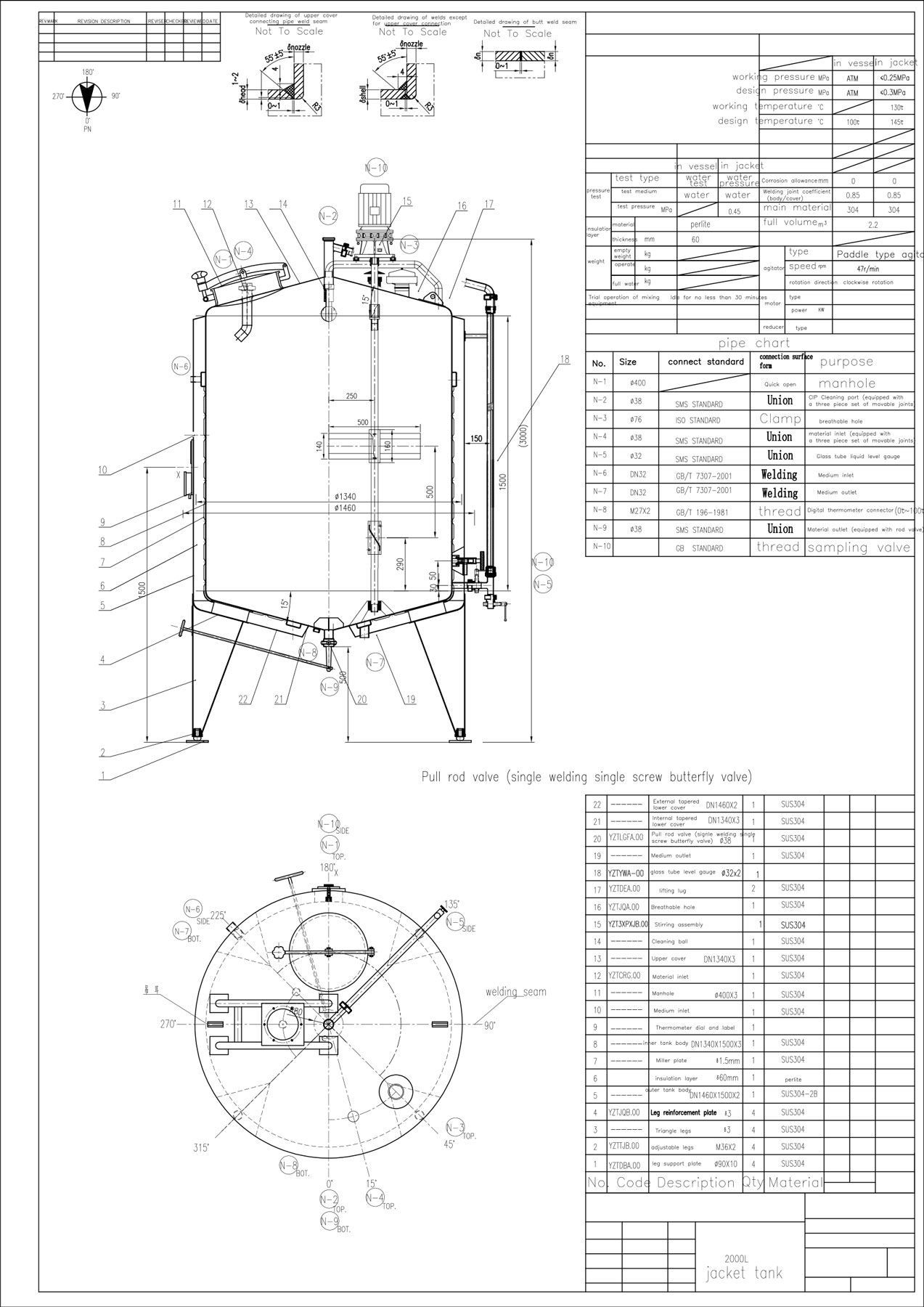

Jacket Tank

2000L- V=2000L

- SUS304

- touch parts with material SUS316

- jacket insulation

- honeycomb plate 1.5mm with an outer layer of 2mm

- 60mm PU heat insulation

- top offset paddle stirring at 20r/min

- SEW motor 1.5KW

- tank body φ1490*1220*3mm

- upper and lower conical heads

- breathing hole

- sampling valve

- CIP balltype sprayer

- climbing ladder

- digital thermometer

- four adjustable legs

Jacket Tank

5000L- V=5000L

- SUS304

- touch parts with material SUS316

- jacket insulation

- honeycomb plate 1.5 mm with an outer layer of 2mm

- 60mm PU heat insulation

- top offset paddle stirring at 20r/min

- SEW motor 2.2KW

- tank body φ1630*2440*3mm

- upper and lower conical heads

- breathing hole

- sampling valve

- CIP balltype sprayer

- climbing ladder

- digital thermometer

- four adjustable legs

Jacket Tank

10000L- V=10000L

- SUS304

- touch parts with material SUS316

- jacket insulation

- honeycomb plate 1.5 mm with an outer layer of 2mm

- 60mm PU heat insulation

- top offset paddle stirring at 20r/min

- SEW motor 3KW

- tank body φ2070*3000*3mm

- upper and lower conical heads

- breathing hole

- sampling valve

- CIP balltype sprayer

- climbing ladder

- digital thermometer

- four adjustable legs

Why you should choose Ferrum Group as your supplier for stainless-steel tanks?

- Highly cost-effective price points compared to European manufacturer market offerings

- High quality products by the best Chinese manufacturers

- All volume sizes available – configuration according to your specifications

- Single point of contact with product expert

- Optional construction, production of piping and other process equipment by Ferrum Group

- Optional installation of stainless-steel tanks by Ferrum team or partners throughout Europe

DOCUMENTATION AND CE MARKING

Download a PDF describing Ferrum Group’s documentation material that accompanies equipment deliveries.

You can read about our three types of documentation and the standards followed by the CE marking, among other things.

TALK TO CARSTEN ABOUT FERRUM GROUP’S HIGHLY AFFORDABLE STAINLESS-STEEL TANKS

Sales Director Carsten Jørgensen and the engineering team have extensive experience in advising industrial companies for optimal solutions in their process plants as well as in robot and automation systems.

Reach out to Carsten to learn more about stainless-steel tanks and to discover more about Ferrum’s offerings.

Visit Ferrum Group’s LinkedIn company page

Carsten can be contacted

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten's LinkedIn profile