■

ROBOTIC TOOLING AND END-OF-ARM TOOLING

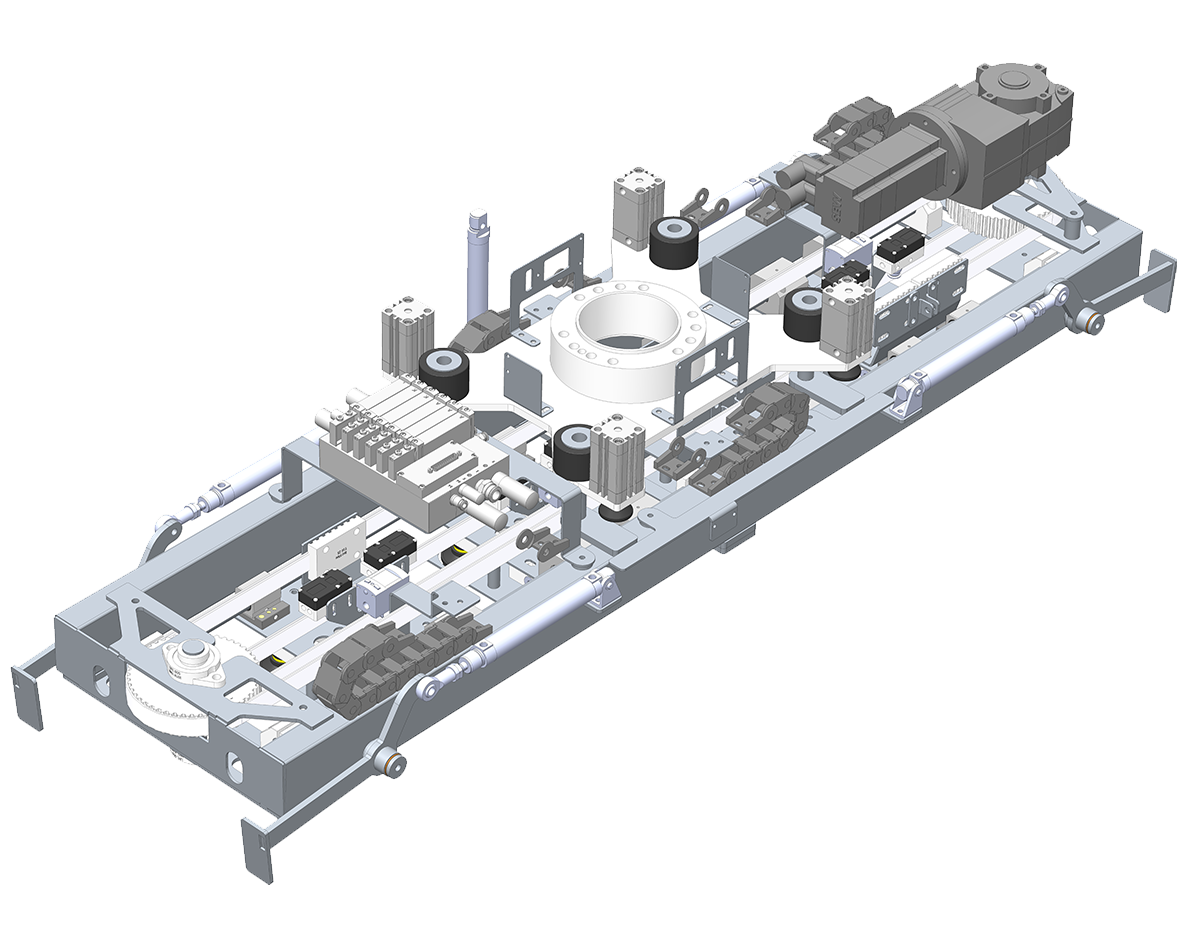

Custom-built robotic tools for industry robots

Ferrum Group has developed a wide range of tailored/customized robot tools for industrial customers, often in connection with End-of-line solutions.

We offer to handle the entire process regarding the production of robotic tools / End-of-Arm Tools: from requirement specification, production, to on-site implementation of robotic tools.

We develop robot tools as stand-alone solutions or as part of integrated robot and automation projects.

Customized robot tools/End-of-Arm tooling make an operational difference.

At Ferrum Group, we have extensive experience in in-house development and production of robot tools for use in industries such as the food industry, including:

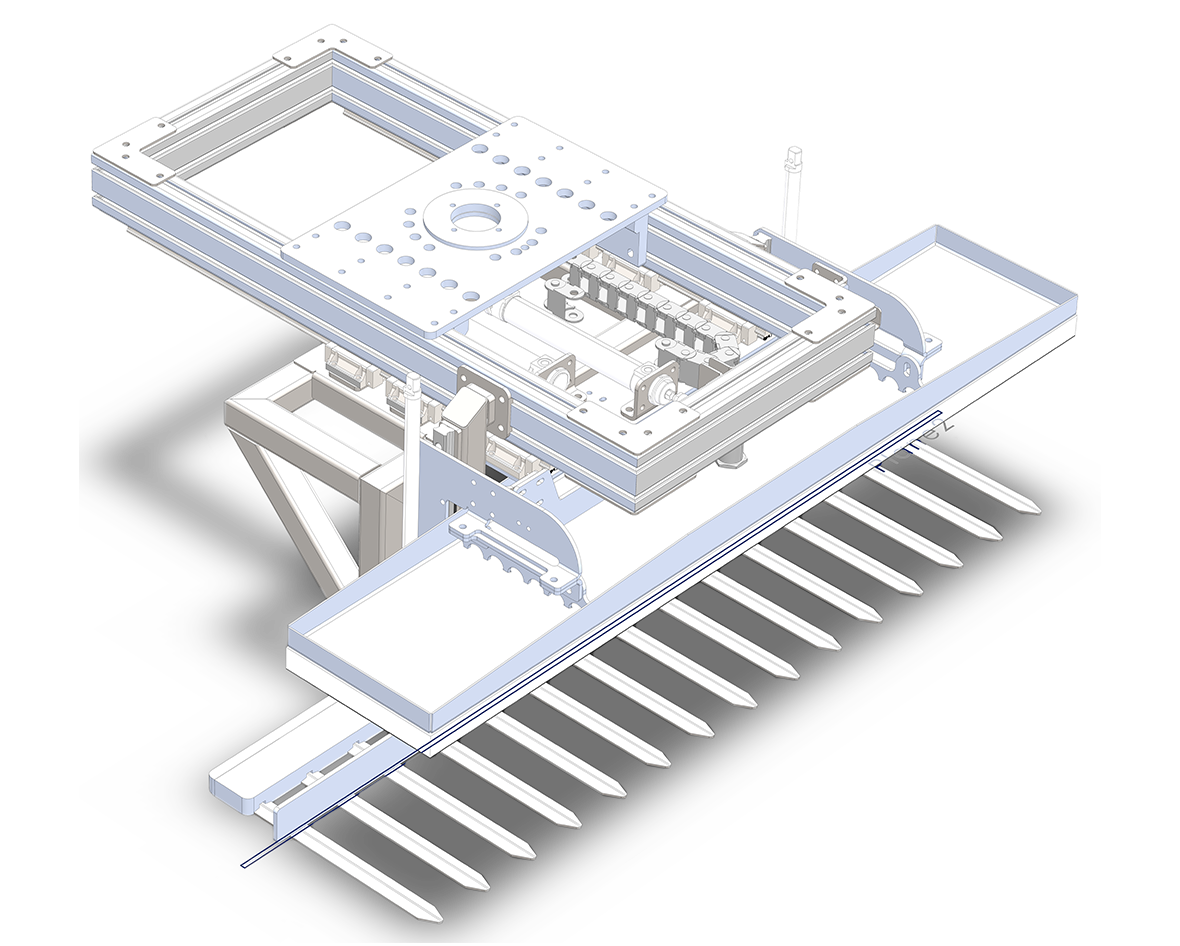

- Vacuum suction/vacuum gripper/vacuum tool/suction gripper – suitable for handling cardboard boxes of all kinds, WA cartons, wrapped products, vacuum-sealed products, closed boxes, and bags.

- Shovel gripper/spade tool/sliding hand – suitable for handling cardboard boxes, trays, and plastic boxes.

- Bag gripper / Sack gripper – suitable for handling bags, typically made of paper and plastic.

- Box gripper – suitable for trays, plastic boxes, internal storage containers, SRS boxes.

We choose the right technology for your solution.

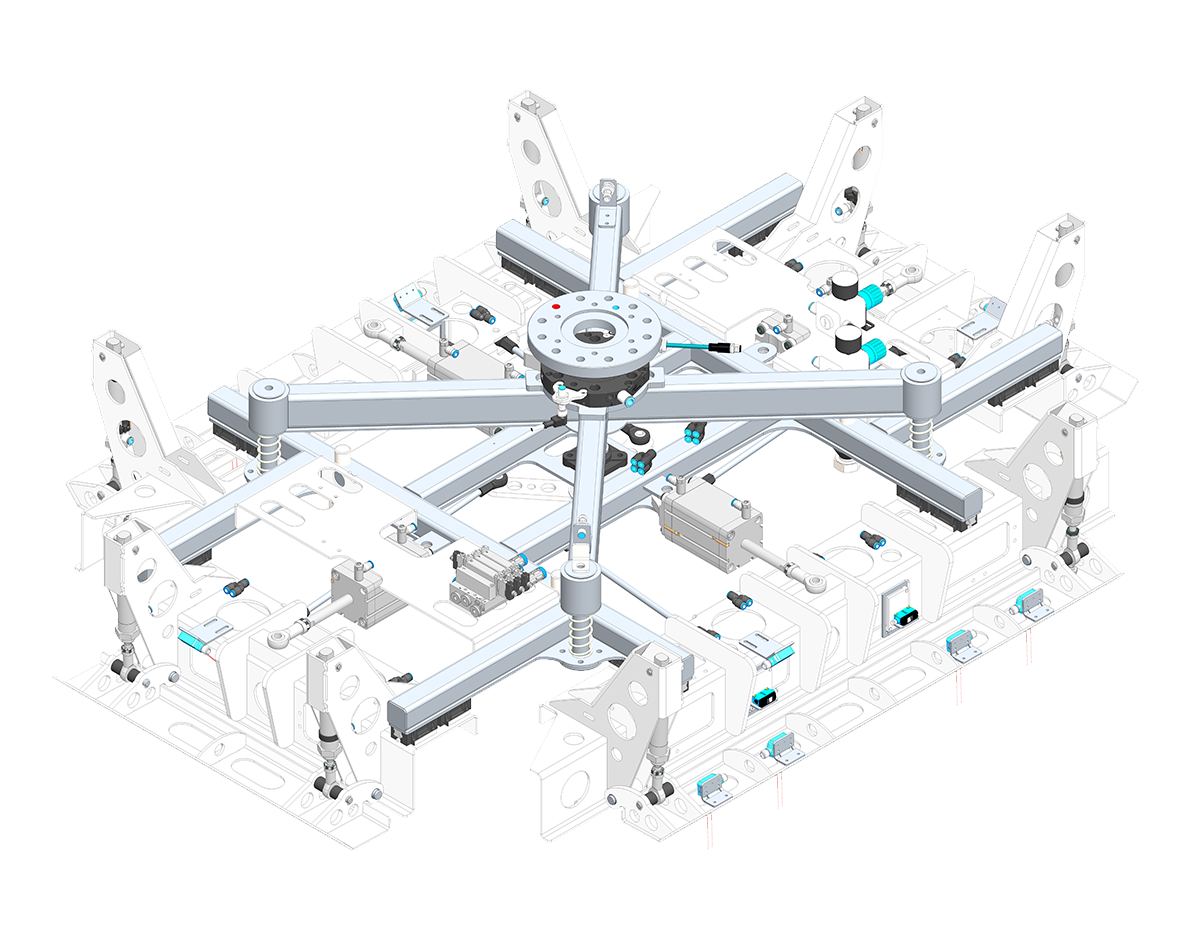

Robot tools/robot end effectors (End of Arm tooling (EOAT)) or robot gripper tools are crucial components in automated robotic arm applications. They are mounted at the end of the robot arm and are used to handle, manipulate, or process materials and objects.

Robot tools/robot grippers come in a wide range of designs to meet different application needs. These gripper designs can include:

- Vacuum grippers: Use vacuum force to attach and lift objects with smooth surfaces, such as sheets or glass.

- Mechanical grippers: Employ mechanical jaws, fingers, or claws to grasp objects of various shapes and sizes.

- Magnetic grippers: Use magnetic attraction to handle metallic items, such as steel sheets.

- Pneumatic grippers: Powered by compressed air and can be used to grip objects of varying shapes and sizes.

- Hydraulic grippers: Use hydraulic power to perform the gripping function, often in applications requiring strong gripping capability.

- Electric grippers: Utilize electric motors to perform the gripping function, and they can offer more precise movements and positioning options.

The choice of technology depends on the specific requirements of the application, such as the shape, size, weight, surface type of the object, and the speed of operation. Hydraulic and electric grippers are two common types that operate using different power sources. Hydraulic grippers are known for their strength and ability to handle heavy loads, while electric grippers are often used when precision and accurate control are necessary.

Choosing the right robot gripper for a given task is important as it can have a significant impact on the efficiency, accuracy, and reliability of the automated production process.

At Ferrum Group, we are available to provide guidance for the right solution. Call us or fill out the contact form below.

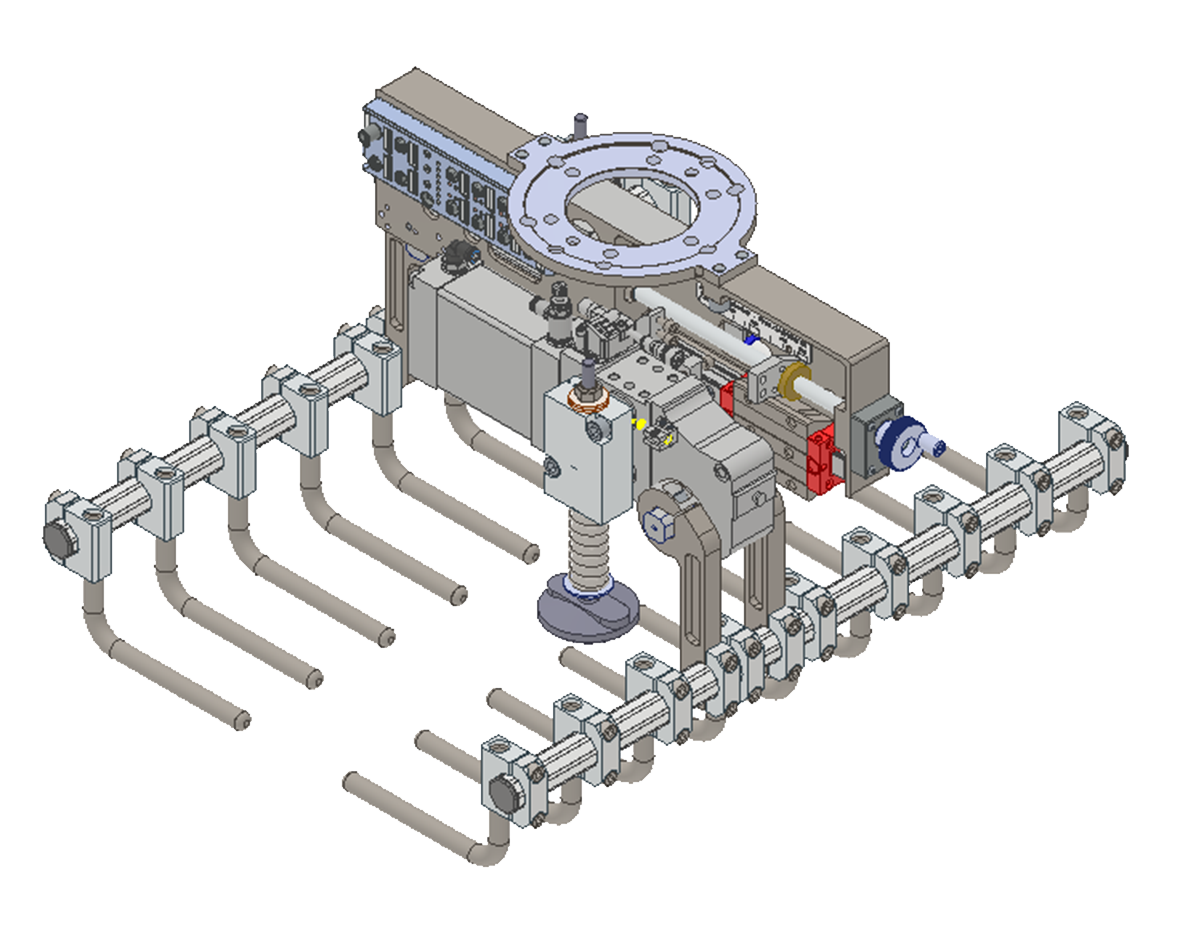

INNOVATIVE ROBOTIC TOOLS

– EXPLORE THE POSSIBILITIES

Download a whitepaper providing an overview of selected robot tools that we have developed for customers in the food industry. The development of efficient robot tools is one of the prerequisites for achieving success in a robot and automation project. Learn more about how we approach the task when constructing customized robot tools for the food industry.

EXPLORE FURTHER INTO FERRUM GROUP’S OTHER AREAS OF EXPERTISE WITHIN ROBOTICS AND AUTOMATION. READ MORE ABOUT:

Turnkey End-of-Line industrial solutions

Primary and Secondary Packaging for Food

Ferrum’s Innovative and Palletizing solutions

Our Solutions for Vision and Quality Inspection

Our Inspection and Rejection Solutions for the Food Industry

TALK TO CARSTEN ABOUT FERRUM GROUP’S ROBOTIC TOOLS – STAND-ALONE OR FULLY INTEGRATED

Carsten Jørgensen is our robotics and automation expert with extensive experience in developing and implementing all types of robotic solutions.

Reach out to Carsten and learn more about the gaining operational efficiency from customized robotic tools.

Visit Ferrum Group’s LinkedIn company page

Carsten can be contacted

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten's LinkedIn profile