■

Filling lines for breweries and the beverage industry

High quality turn-key filling line and packaging solutions at cost-effective price points

At Ferrum Group, we collaborate with highly capable manufacturing partners to provide filling lines tailored for the beverage, brewery and food industries, delivered as turnkey solutions.

Our expert team consists of Dirk Cichon, who served as CEO of Krones Nordic for 40 years. Dirk now brings his extensive technical expertise and experience from the supplier side to the role of advisor and brewery consultant, offering unmatched insight for our customers.

Keld Norup Lauridsen brings over 40 years of highly valuable experience from the buying side, having served as plant director at Carlsberg and manager at Royal Unibrew.

Peter Høegh Jensen, CEO of Ferrum Group, along with Carsten Jørgensen, our sales director, are industry experts. Peter has extensive experience as a plant director at Carlsberg and Coca-Cola, while Carsten has served as a plant manager in can manufacturing. This team will guide you from the first point of contact to final installation and commissioning.

Our complete turnkey delivery encompasses process equipment, cutting-edge filling technology, and innovative packaging solutions, all crafted by world-leading companies specializing in brewery equipment at cost-effective price points.

With a proven track record of serving esteemed brands such as Heineken, Coca-Cola, Pepsi, Tsingtao and Carlsberg in the Asian region, our manufacturing partners showcase an unwavering capability to deliver unparalleled solutions.

Our product range spans PET and glass bottle filling lines and can filling lines, offering various capacities as well as customized packaging solutions to meet diverse needs.

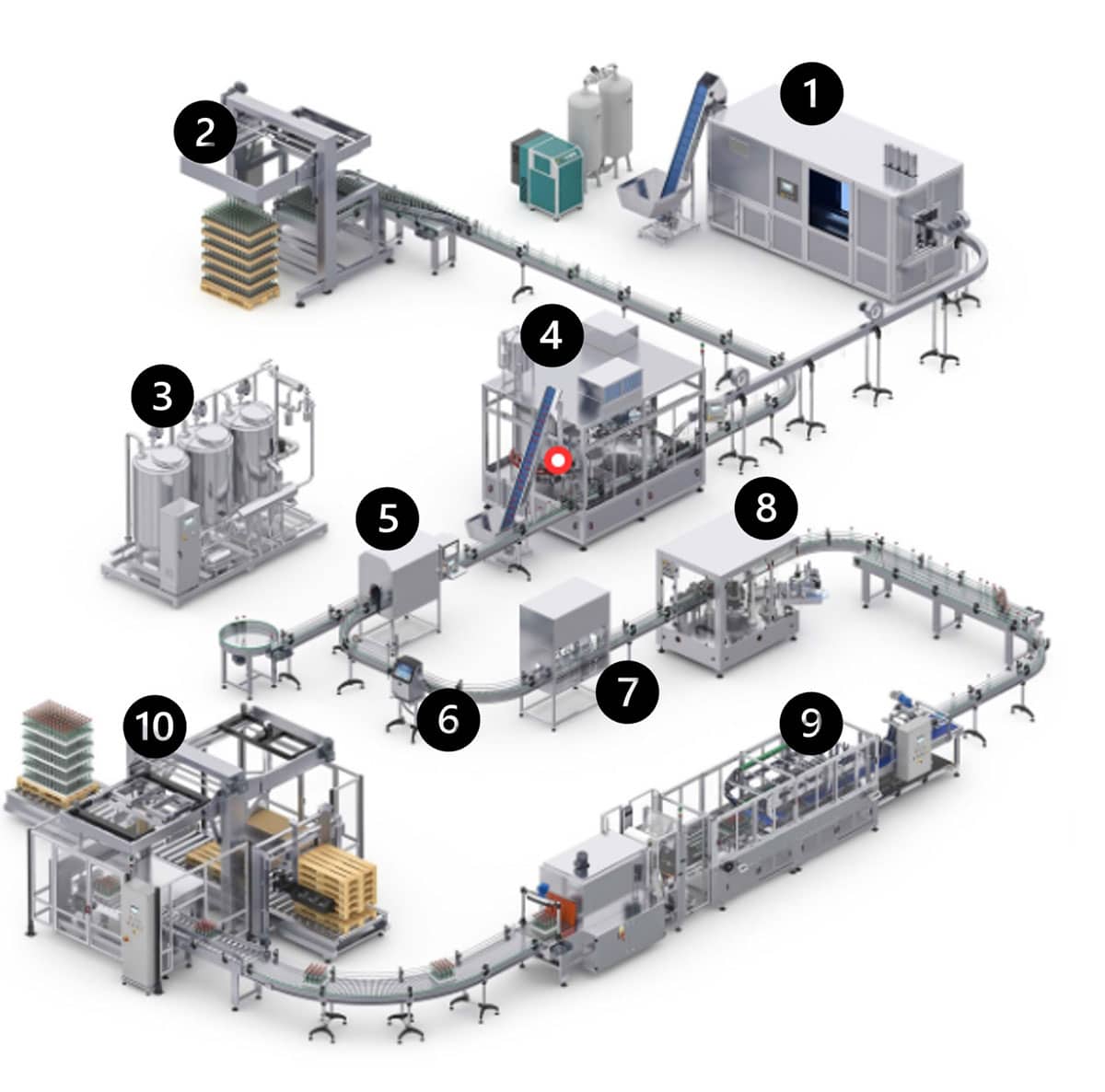

Filling line configuration

Ferrum Group supplies turn-key solutions as well as single machines that fits into existing production and filling lines.

We offer filling lines with capacities ranging from 6,000 to 60,000 products per hour. Our manufacturing partner has over 23 years of experience in the filling industry, with more than 500 filling lines currently in operation worldwide.

Here’s a non-exhaustive list of typical installations in beer and beverage filling lines:

- PET blowing machine: Efficient machinery to shape preforms made from polyethylene terephthalate (PET) into plastic bottles through a blow molding process

- Depalletizer: Machinery to remove layers of bottles or cans from pallets to be fed into the filling and packaging line

- Saturator: Infusing of beverages (often carbon dioxide) to achieve desired level of carbonation prior to filling

- Rinsing, filling and capping: Custom machinery for cleaning, filling and closing of containers

- Inspection machine: Equipment to monitor and control filling levels in containers depending on needs

- Marking printer: Device used to print codes or dates onto containers as they move through the production line

- Blowing dryer: Machinery used to dry e.g. glass bottles before labels are applied

- Labeling machine: Device used for applying labels to bottles and cans

- Packing machine: Process to package filled bottles or cans into boxes or cartons. In addition to packaging, we offer solutions for shrink wrapping/bundling according to needs

- Palletizer: Automated stacking solutions of filled containers onto pallets for storage and transportation

- Conveyor systems: Customized conveyors depending on factors such as: speed, capacity, layout, size and layout. Safety, reliability, sanitation/cleanliness are other factors often taken into account.

Why you should choose Ferrum Group as your supplier for filling lines?

- Single point of contact with an expert team with many years of experience in the brewery and beverage industry

- Our team will guide you from the initial layout possibilities to the final project scope (turnkey delivery)

- All equipment is manufactured by the same supplier

- All components sourced from global and reliable suppliers

- Extended scope of commissioning and training of operators on site

- Consignment stock of spare parts minimizes downtime

- Spare parts package covering two years of production (1 shift) included in the project price

- Highly cost-effective price points compared to market incumbent offerings

EXPLORE LAYOUT EXAMPLES OF CAN AND BOTTLE FILLING LINES WITH VARYING CAPACITIES. ALL SOLUTIONS ARE BUILT ACCORDING TO YOUR SPECIFICATIONS AND VOLUME NEEDS

Filling line – capacity 6.000 bottles per hour

Filling line – capacity 12.000 cans per hour

Filling line – capacity 15.000 bottles per hour

Filling line – capacity 30.000 cans per hour

World-leading components and spare parts suppliers

For all our projects, we exclusively utilize global suppliers to ensure the supply of high-quality products, continuous support, and prompt spare parts delivery.

Efficient spare parts management minimizes your production downtime

In order to secure minimum downtime in your filling line production process, we include a spare parts package covering two years of production (1 shift) into the project proposal by default – unless otherwise specified.

We’ve built a strong spare parts concept providing value to our customers through:

- Close and strong partnerships with supplier distribution network

- Consignment stock placed at our site in Fredericia, Denmark

- Spare parts manufacturing at our own factory in Fredericia, Denmark

- Maximum 72 hours delivery time on stock items throughout Europe

- Single point of contact for all spare part related inquiries (7 days)

CASE: CARBONATED COCKTAIL FILLING LINE

The bottle filling line contains bottle infeed, a water treatment system, filling and capping, mixer and tunnel pasteur, labelling and a shrink tunnel. Please contact us if you have questions regarding our innovative filling lines and packaging solutions at highly competitive prices.

DOCUMENTATION AND CE MARKING

Download a PDF describing Ferrum Group’s documentation material that accompanies equipment deliveries.

You can read about our three types of documentation and the standards followed by the CE marking, among other things.

Our expert team will serve and guide you from inquiry to commissioning

Peter Høegh Jensen

CEO Ferrum Group

2012 – present, CEO of Ferrum Group

2003 – 2012 – Plant Director, Can manufacturer and Carton supplier

1995 – 2003 – Carlsberg/Coca Cola. Plant Director and Maintenence responsible

Dirk Cichon

Brewery Consultant

1982 – 2023 CEO of Krones Nordic, Global supplier of filling lines.

Keld Norup Lauridsen

Brewery Consultant

1975 – 2010 Carlsberg Breweries.

- Department and operations manager

- Brewery manager

- Implementation of new filling lines.

2010 – 2023 Royal Unibrew

- Plant Director Faxe plant incl. Brew house responsible (3 Mio HL).

- 5 Canning lines, 2 PET lines, 1 Glass line, 1 KEG line, 1 bag in Box line

Carsten Jørgensen

Sales Director Ferrum Group

2018 – present, Sales Director of Ferrum Group

2014 – 2018, Production Manager Jorgensen Engineering.

2004 – 2014 Envases Universales Europe – Can Manufactoring Company.

- Plant Manager of Can/LID Production (2008-2014)

- Production Manager of Can/LID Production(2005-2008)

- Project Manager – New UV – 6 Color Printing line (2004-2005)

Henrik Bebe

Project Director Ferrum Group

2023 – present, COO / Project Director Ferrum Group

2019 – 2023, Head of projects and production, Ferrum Group

2017 – 2019, Technical manager, Ferreo A/S

2014 – 2017, Technical and quality manager, PipeCon – ARM Steel Solutions

Michelle Song Eriksen

Strategic purchaser with 15 years of experience sourcing from China

2019-2023 Vestas – Purchasing Manager, Global Procuremen

2018 Danish Crown – Group Category Manager MRO & Spare Parts, Group Procurement

2014-2018 Vestas – Senior global commodity lead, Global Procurement

TALK TO CARSTEN ABOUT FERRUM GROUP’S INNOVATIVE FILLING LINES AT COST-EFFICIENT PRICE POINTS

Carsten Jørgensen and the remaining filling line and beverage expert team has extensive experience in developing and implementing automated turn-key solutions for the beverage and brewery industry.

Reach out to Carsten learn more about Ferrum’s offerings.

Visit Ferrum Group’s LinkedIn company page

Carsten can be contacted

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten's LinkedIn profile