■

Primary and secondary

packaging

Automated primary and secondary food packaging solutions

At Ferrum Group, we develop custom solutions for primary packaging of unpackaged food products. We provide solutions that adhere to design regulations, traceability, and certifications, all of which are in line with the requirements of EHEDG (European Hygienic Engineering & Design Group). We have experience in primary packaging of finished products in their final customer packaging, as well as wrapping and packaging of products for further internal or external processing.

We supply thermoformers and deep-draw packaging machines as part of a comprehensive solution, but we also have the capability to integrate with packaging solutions provided by other suppliers.

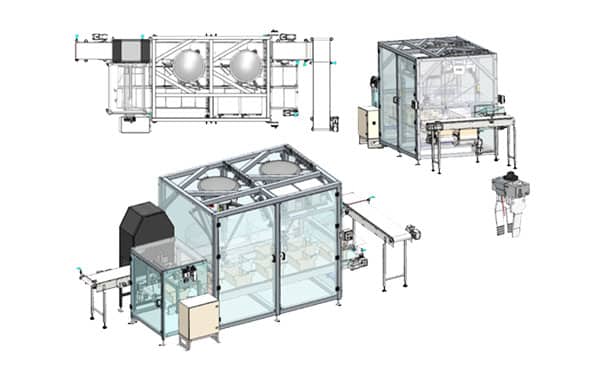

Case Primary Packaging – Handling and Loading of Mozzarella Blocks in GEA PowerPak

- GEA, CMT Plant for Mozzarella Production

- GEA is a turnkey provider of the process line

- Ferrum Group is the supplier of the robotic system for handling and loading of Mozzarella blocks in GEA’s PowerPak

- Capacity 4-8 tons of Mozzarella cheese per hour

- Products 2.5 kg Mozzarella blocks. In addition to the hardware delivery

- Our scope of supply also include: Idea generation, Solution and layout development, Equipment development and design according to EHEDG (European Hygienic Engineering & Design Group) principles, Software for PLC, HMI, and Robots, as well as communication with superior systems.

Secondary packaging solutions for packaged foods

Secondary packaging involves a packaging process where products in their primary packaging are placed into, for example, cardboard or plastic boxes, which are then palletized. We have extensive experience in developing solutions for secondary packaging of all types of food products. In the process between packaging and palletizing, we can integrate control mechanisms such as leak tests.

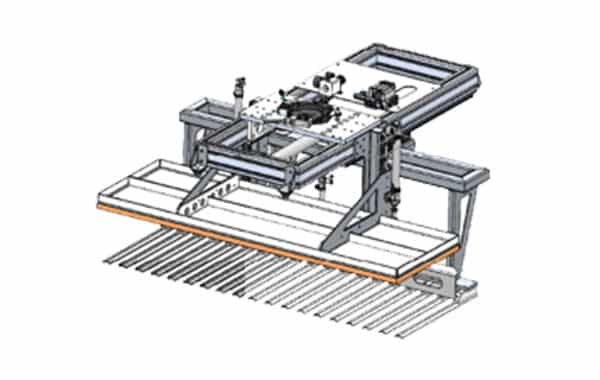

Peripheral equipment for secondary packaging

Stretch wrappers and pallet labelers are typically solutions we provide as the final component in a turnkey solution. However, we also have the capability to deliver equipment for wrapping, label application, inkjet printers, metal detectors, checkweighers, label inspection/visual control, banding machines, etc. on pallets as an integrator/standalone solution.

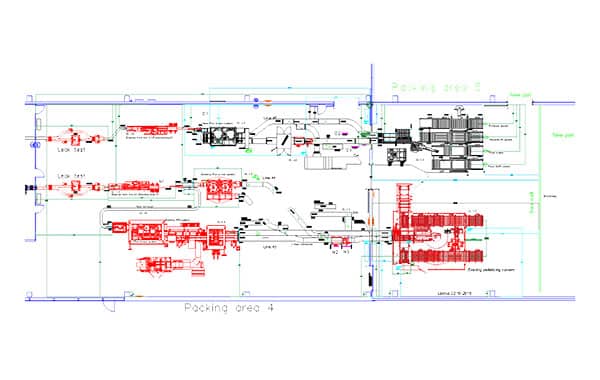

Case Secondary Packaging and Palletizing in a Danish Dairy

Solution

Turnkey solution for end-of-line

Execution of solution

- Idea generation

- Solution and layout development

- Machine development and construction

- Integration of third-party equipment

- Relocation and integration of existing equipment

- Software for vision, PLC (PackML), HMI, and Robots, as well as communication with superior systems

- Project management

- Documentation and CE marking

EXPLORE FURTHER INTO FERRUM GROUP’S OTHER AREAS OF EXPERTISE WITHIN ROBOTICS AND AUTOMATION. READ MORE ABOUT:

Turnkey End-of-Line industrial solution

Ferrum’s Innovative and custom-built Robotic Tools

Ferrum’s Innovative and Palletizing solutions

Our Solutions for Vision and Quality Inspection

Our Inspection and Rejection Solutions for the Food Industry

TALK TO CARSTEN ABOUT FERRUM GROUP’S SOLUTIONS FOR PRIMARY AND SECONDAY PACKAGING

Carsten Jørgensen is our robotics and automation expert with extensive experience in developing and implementing robotic and automation projects.

Reach out to Carsten and learn more about Ferrum’s offerings within food packaging solutions.

Visit Ferrum Group’s LinkedIn company page

Carsten can be contacted

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten's LinkedIn profile