■

Palletizing

Palletizing for all Industries – The Food & Beverage Industry is our Expertise

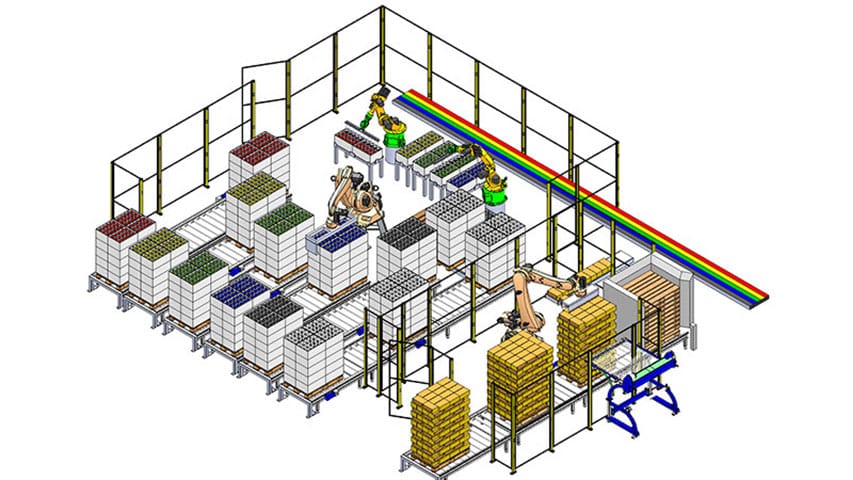

At Ferrum Group, we’ve developed a wide range of customized palletizing solutions, particularly for the F&B industry. An End-of-Line palletizing solution primarily consists of a robotic arm with a robot/robotic tool, combined with transport and logistics systems to support the solution. The success of a palletizing solution largely depends on the quality and performance of the robotic tool or robot head. That’s why we develop and manufacture the specific robot tools ourselves to handle our customers’ products. This gives us the flexibility to create high-performance palletizing solutions capable of handling a wide variety of product types in the food industry.

Learn more about our specially developed robotic tools here.

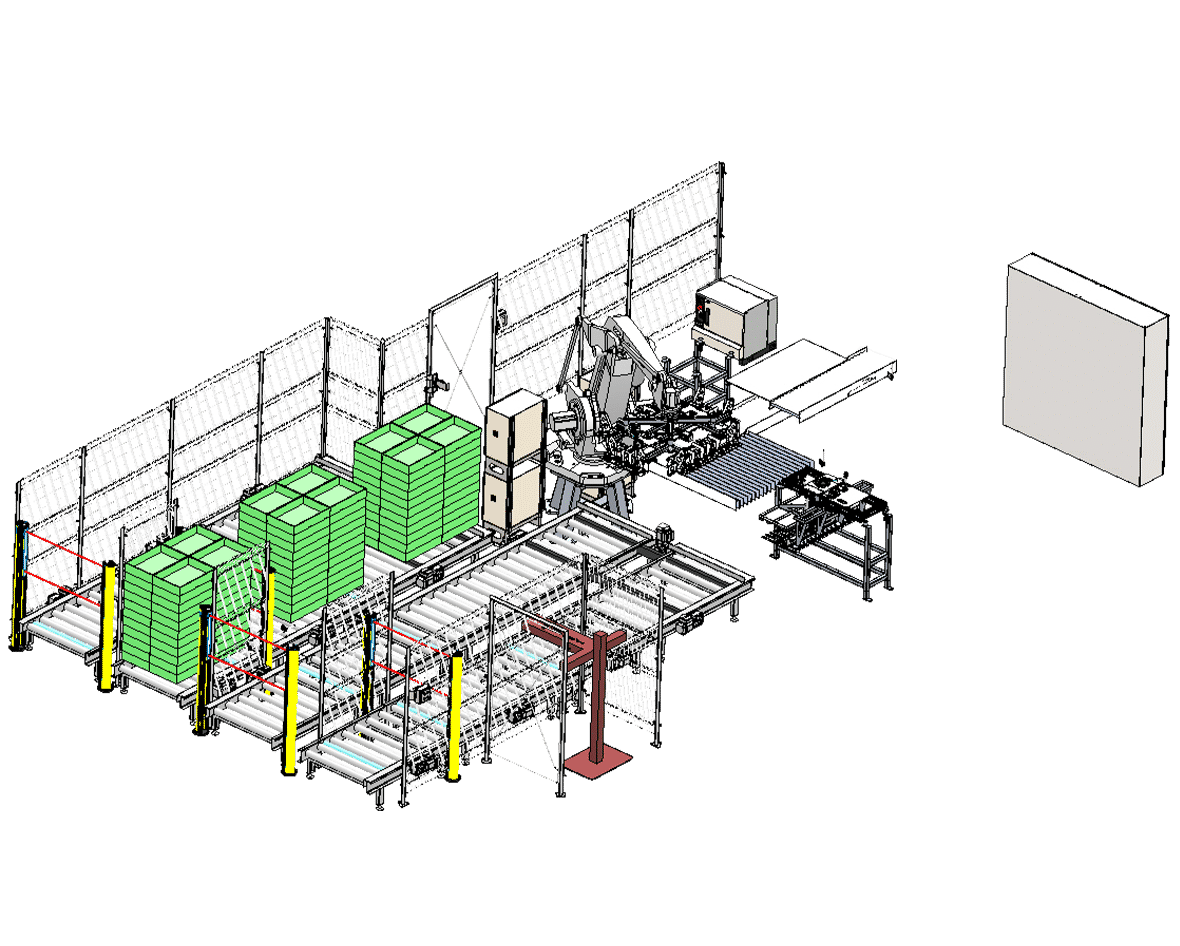

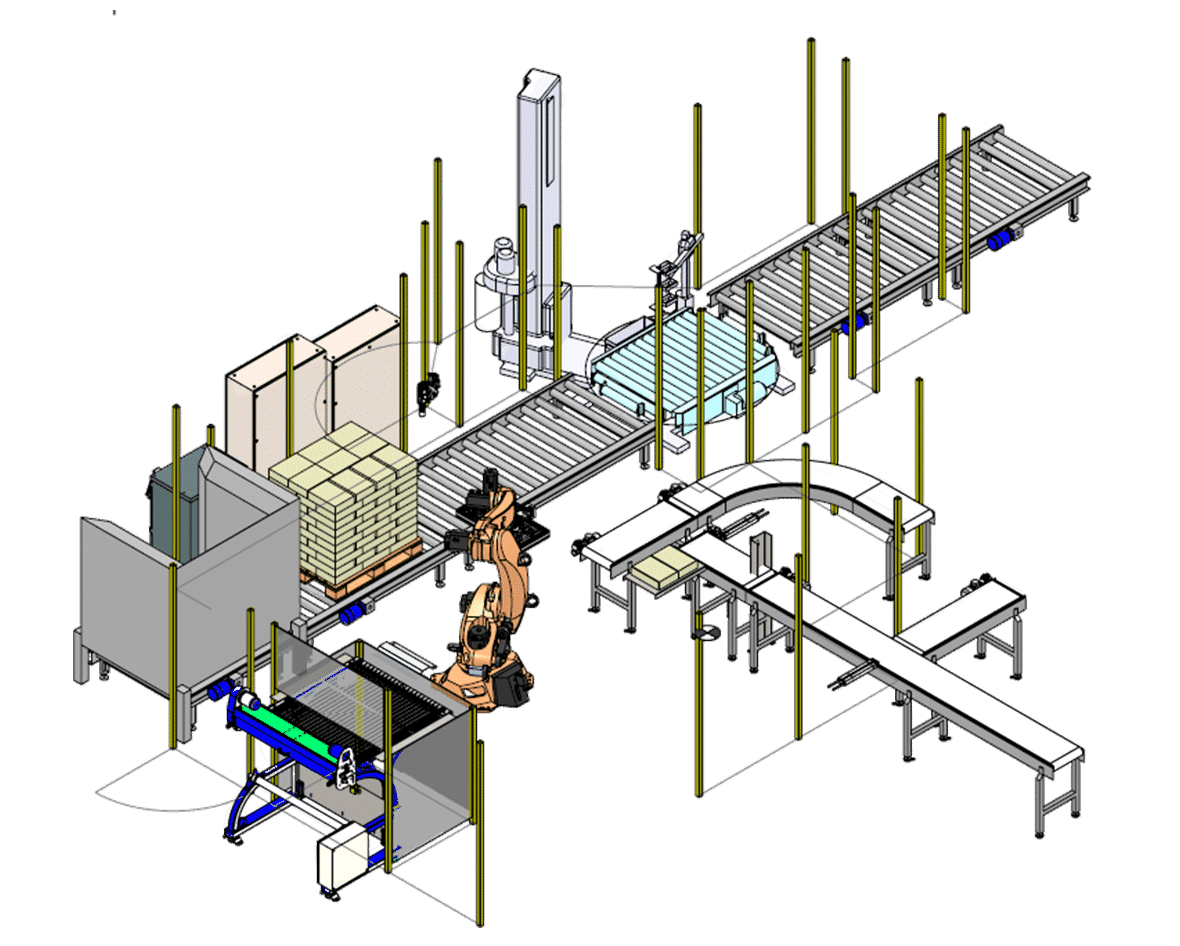

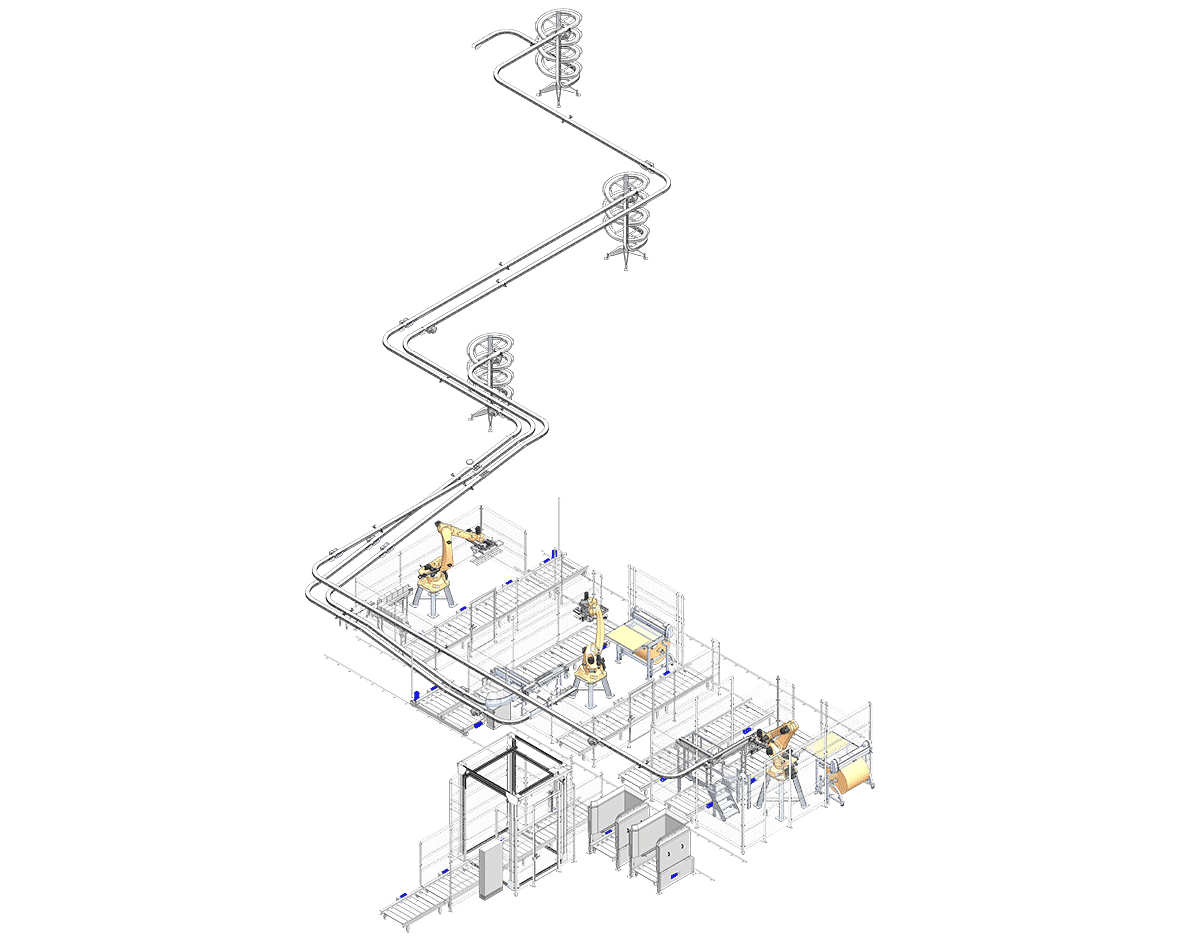

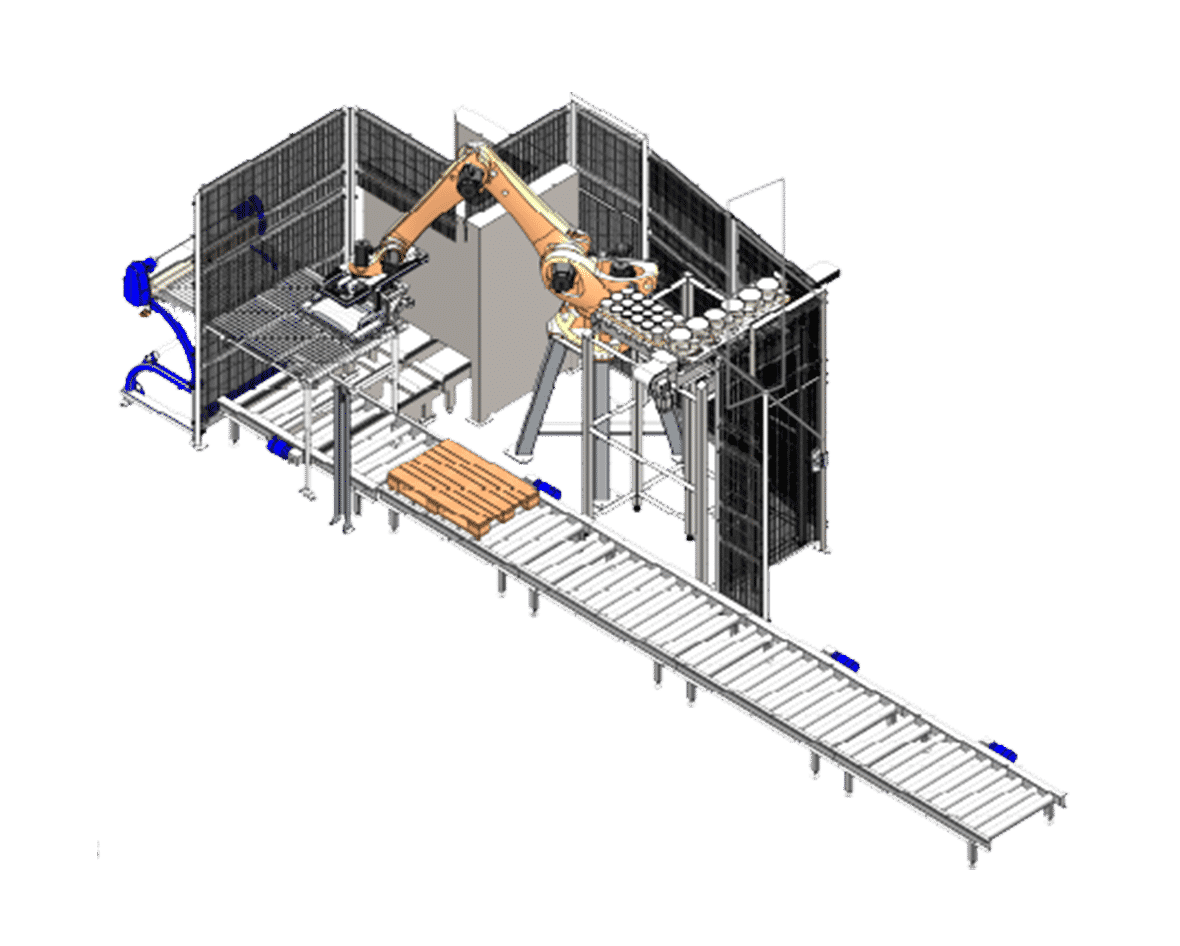

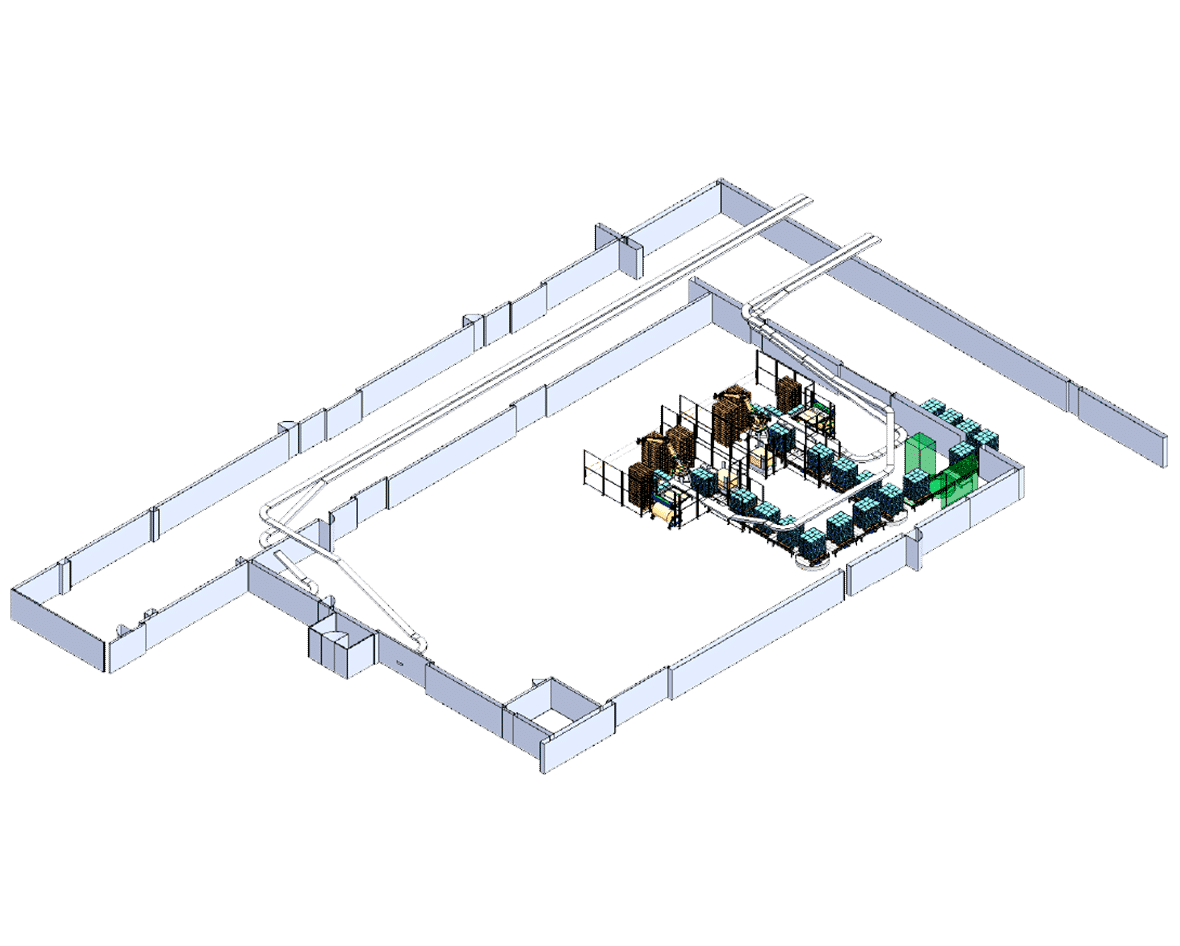

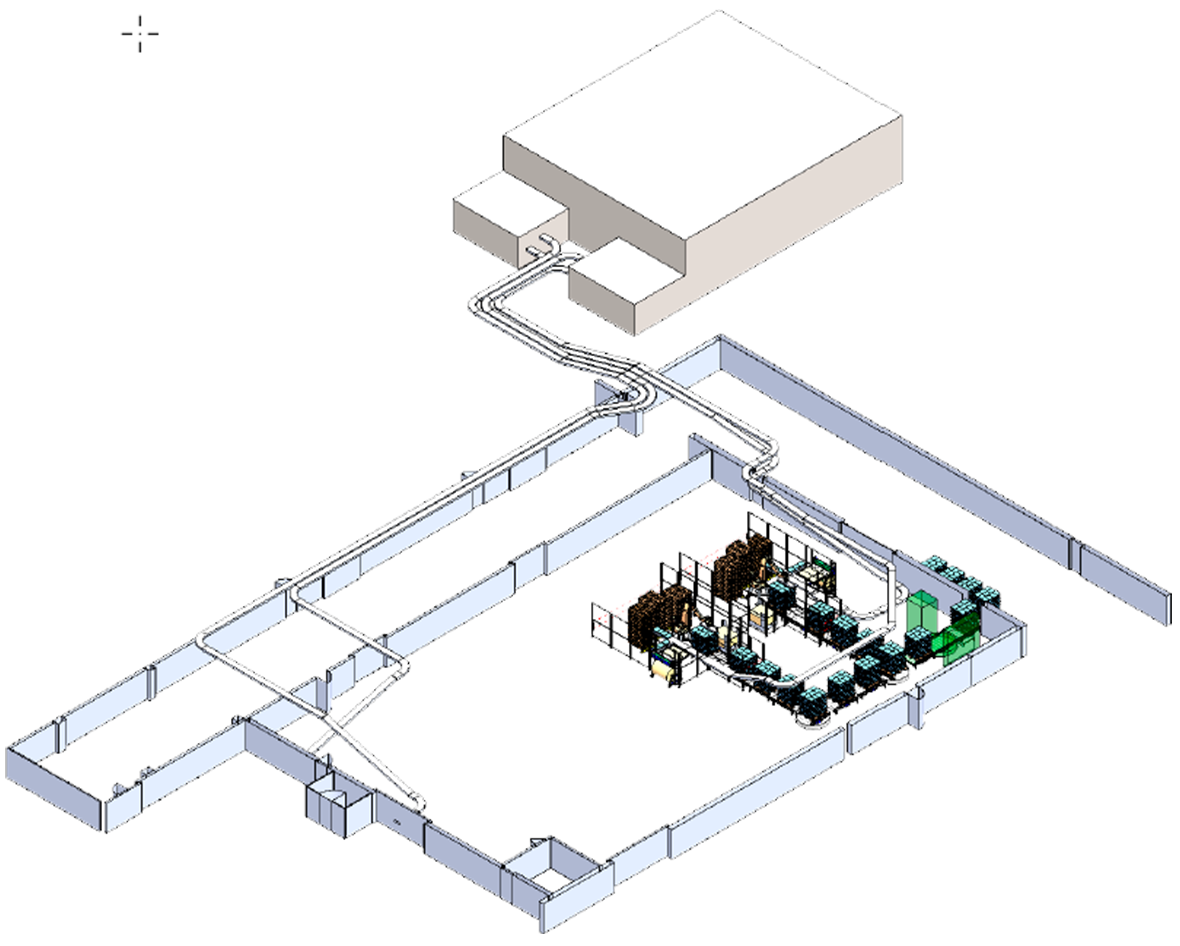

Automated palletizing customized to your factory layout

The solutions are tailored to your current factory layout and your desired product flow, and existing or new peripheral equipment such as stretch wrappers or pallet labeling can be integrated.

We develop and adapt stand-alone palletizing cells or turnkey solutions for the specific task, always focusing on the following key points:

- Full flexibility

- High capacity

- Minimization of product waste

- Modularity and scalability of the solution

- High level of accessibility for operation, cleaning, and servicing

- Hygiene

- Material selection

- Safety

Palletizing of Products:

Palletizing involves a process where a robotic arm with a customized robot tool grips an item on a conveyor and places it on a pallet in a specific pattern.

Depalletizing:

Depalletizing is a process where a robotic arm picks products from a pallet and feeds them into a processing system. In the food industry, the robot primarily handles products packaged in their primary packaging, such as films, bags, or empty plastic crates.

Mixed Case Palletizing & Mixed Packing:

Mixed packing is a process where different product variants are packed in the same box or packaging. This can be provided as a standalone system or integrated into a packaging line, where products from the production line are packed along with additional items, for instance, from a pallet or conveyor.

Mixed palletizing is a process where different boxes/products are automatically palletized onto the same pallet, customized for delivery to retail customers, for example.

EXPLORE FURTHER INTO FERRUM GROUP’S OTHER AREAS OF EXPERTISE WITHIN ROBOTICS AND AUTOMATION. READ MORE ABOUT:

Turnkey End-of-Line industrial solutions

Primary and Secondary Packaging for Food

Ferrum’s Innovative and custom-built Robotic Tools

Our Solutions for Vision and Quality Inspection

Our Inspection and Rejection Solutions for the Food Industry

TALK TO CARSTEN ABOUT FERRUM GROUP’S PALLETIZING SOLUTIONS

Carsten Jørgensen is our robotics and automation expert with extensive experience in developing and implementing all types of custom palletizing solutions.

Reach out to Carsten and learn more about the options of optimizing palletizing processes in your company.

Visit Ferrum Group’s LinkedIn company page

Carsten can be contacted

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten's LinkedIn profile