■

END OF LINE SOLUTIONS

– FOOD & BEVERAGE

The food and Beverage Industry is our expertise

At Ferrum Group, we have delivered a wide range of fully automated and custom End of Line projects to the food industry, which has granted us deep expertise in food handling. Our approach to projects is to take ownership and responsibility throughout the process. We seek to understand our customers’ businesses and needs so that our commitment and project management create the optimal conditions for the project—whether we’re developing custom machinery, designing larger automation solutions, or optimizing existing End of Line setups.

Turnkey/Full-Service Robotics and Automation Partner

Our specialized team of development engineers, machine designers, and project managers ensures high expertise from start to finish. Most parts and components are manufactured in Ferrum Group’s modern production facilities at the Danish Fredericia site, guaranteeing high quality and delivery reliability throughout the project—along with a competitive market price. With our team and production setup, we are not bound by standard solutions; instead, we develop tailored End of Line solutions that address specific tasks for our customers—with a focus on capacity, performance (OEE), quality, and short equipment changeover times. We handle the project from A to Z and remain independent of subcontractors—from initial concept development to service setup.

Value Creation through Innovation and Supplier Independence

We approach tasks with an innovative and positive mindset. Over the years, we’ve accumulated knowledge and insights from our customers and our network of high-tech suppliers—with the aim of creating maximum value in each individual project. We are independent and work with all major robot and equipment suppliers, allowing us to choose the technological platform that creates the most value and best solves the task for each customer.

EXPLORE FURTHER INTO FERRUM GROUP’S OTHER AREAS OF EXPERTISE WITHIN ROBOTICS AND AUTOMATION. READ MORE ABOUT:

Ferrum’s Innovative and Palletizing solutions

Primary and Secondary Packaging for Food

Our Solutions for Vision and Quality Inspection

Our Inspection and Rejection Solutions for the Food Industry

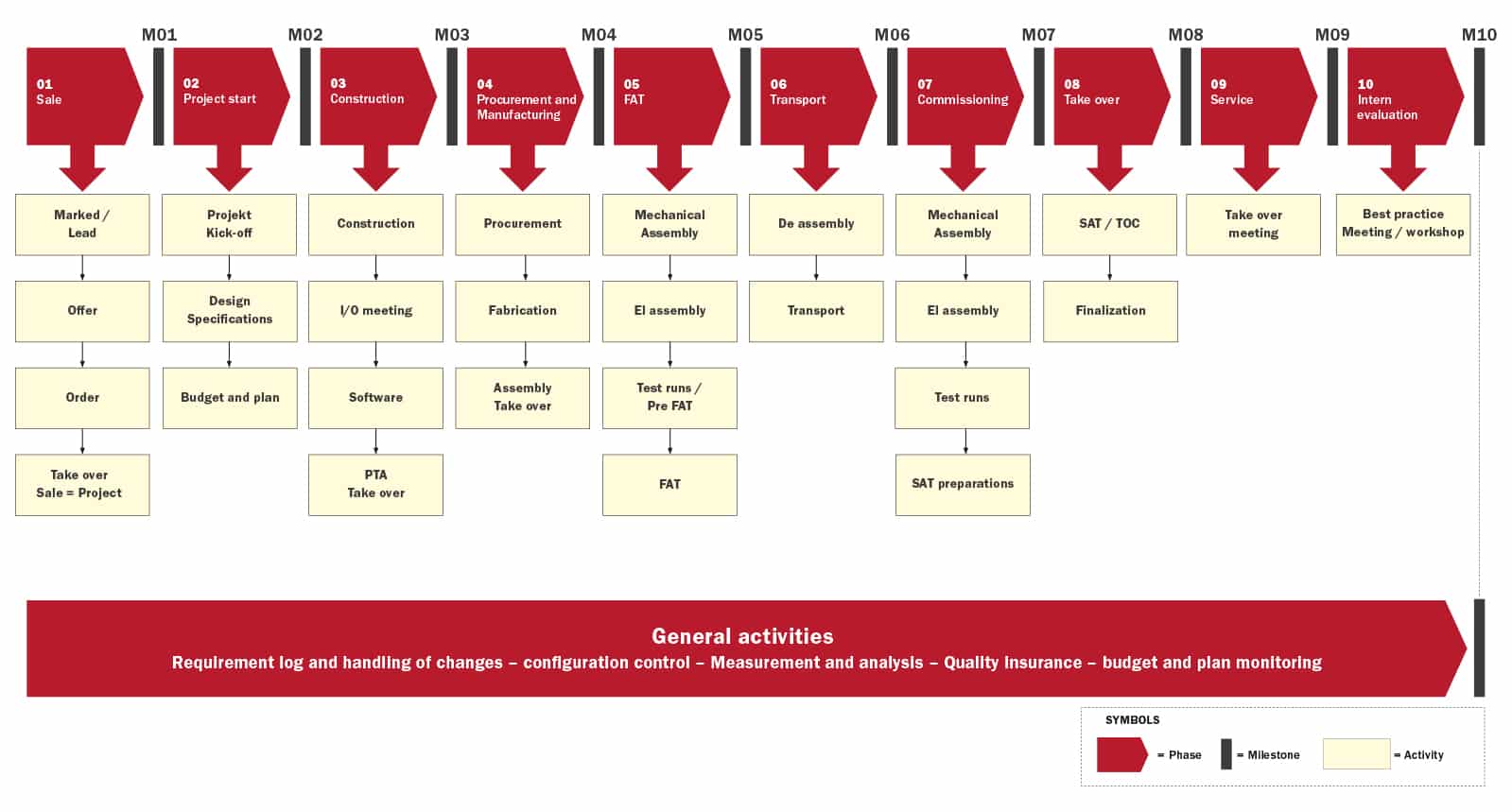

THE FERRUM GROUP PROJECT MODEL:

FOCUS ON QUALITY AND PROGRESS

Our role as a turnkey provider of robotics and automation solutions demands robust project management. Building on the principles of the stage-gate model, we’ve developed a project model that ensures solution quality, as well as progress and adherence to timelines:

- Our project managers ensure rigorous project control to meet deadlines.

- We maintain a continuous flow of information among all project participants, both internally and externally.

- Clearly defined specifications ensure transparency.

- Project management emphasizes critical milestones, approved by the steering committee upon completion of the project’s layout.

DOCUMENTATION AND CE MARKING

Download a PDF describing Ferrum Group’s documentation material that accompanies equipment deliveries.

You can read about our three types of documentation and the standards followed by the CE marking, among other things.

TALK TO CARSTEN ABOUT FERRUM GROUP’S END-OF-LINE SOLUTIONS

Carsten Jørgensen is our robotics and automation expert with extensive experience in developing and implementing all types of End-of-Line solutions.

Reach out to Carsten and learn more about the options of optimizing palletizing, packaging, product handling and more in your company.

Visit Ferrum Group’s LinkedIn company page

Carsten can be contacted

by phone: +45 5125 5158 or

by email: caj@ferrum-group.dk

See Carsten's LinkedIn profile